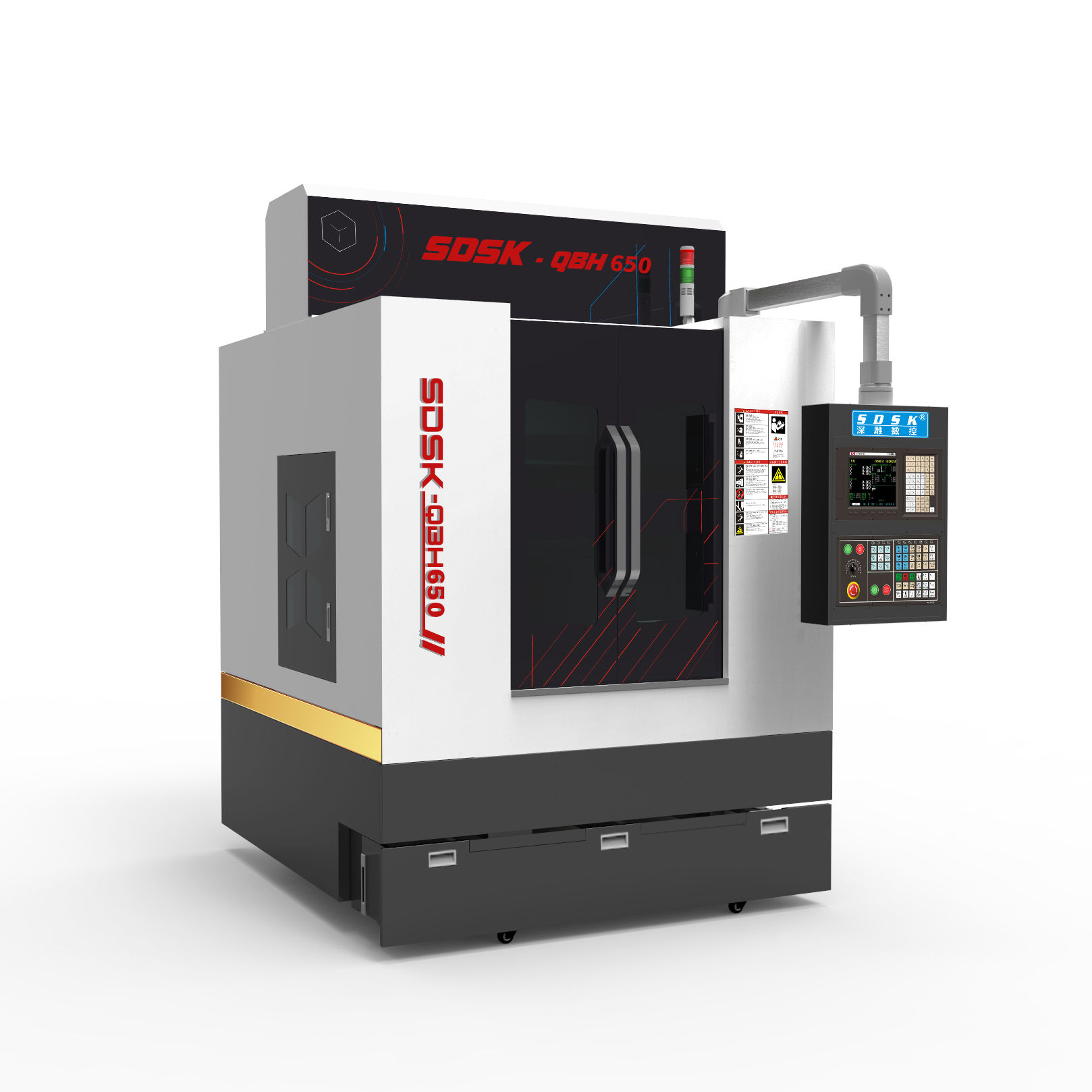

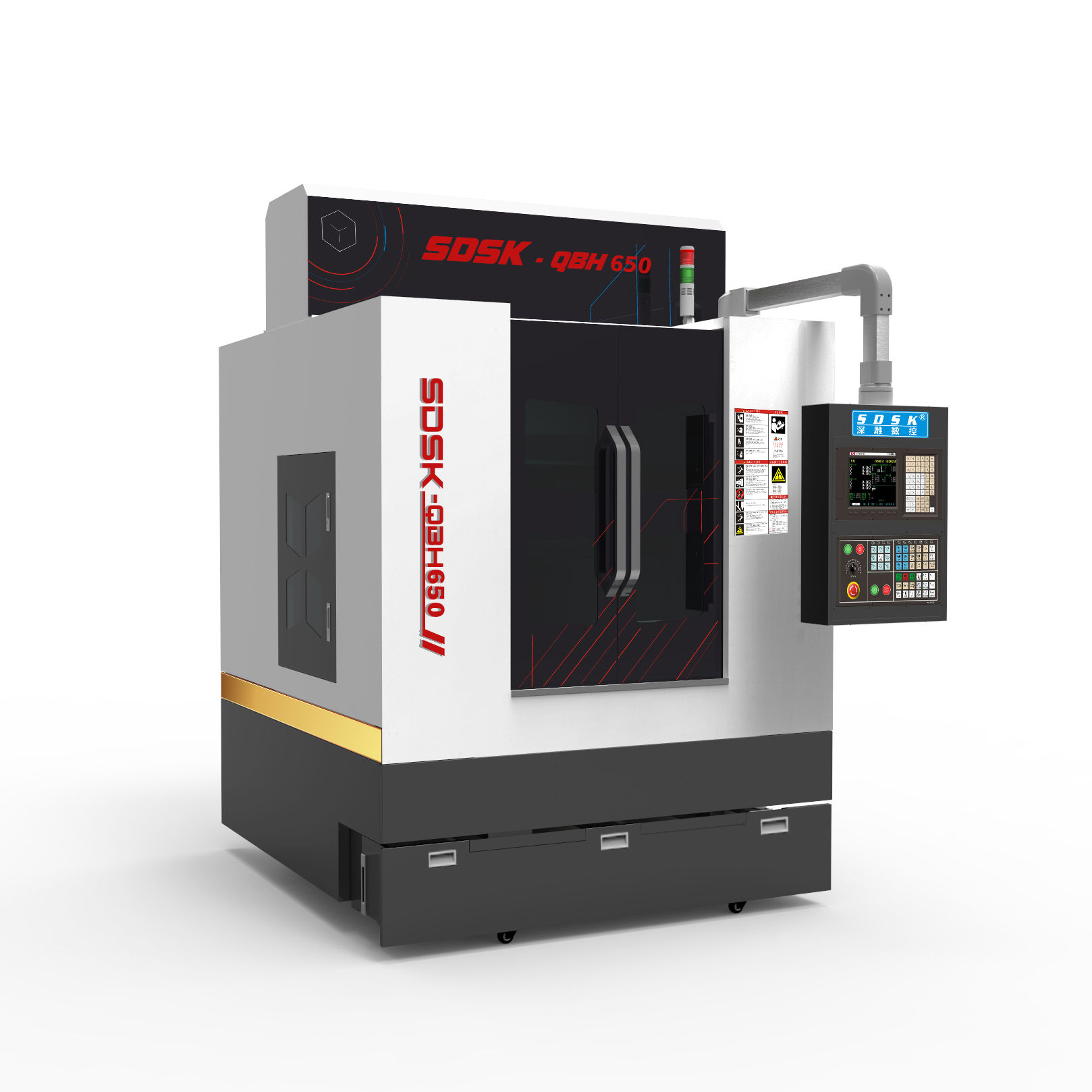

machining center, precision carving machine, cnc machine tool, drilling and tapping machine

1、 machine introduction:

1. the sdsk-qbh650-hske32 model is a three axis fully closed loop high-speed precision carving machine specially designed for customers; equipped with a double row straight 18 position tool magazine; the movement mode is to move the y-axis workbench forward and backward, the x-axis to move left and right, and the z-axis to move up and down< br/>

2. fixed beam gantry structure; the body adopts a top-notch granite (marble) structure that never deforms; xyz adopts imported taiwan shangyin precision linear guide rail, grinding grade ball screw, equipped with servo motor and optical ruler, german coupling, distribution cabinet constant temperature system, advanced spindle cooling system, automatic lubrication system, coolant circulation water spray system, air filtration device, ensuring higher processing accuracy, speed and stability< br/>

3. especially suitable for precision highlight, engraving and milling, drilling and other processing of various types of stainless steel, copper, aluminum, carbon fiber, pc, acrylic, plastic and other parts< br/>

4. additional four rotation axes and probes can be installed< br/>

(the pictures are for reference only, subject to the actual product)

list of main machine configuration (unit: mm)

number

regulations; grid; speak; bright

quantity

origin

new generation cnc system - full closed-loop

1 set

taiwan

xyz axis equipped with 1.0kw new generation servo motor, z-belt clutch

1 set each

taiwan

new generation frequency converter

1 unit

taiwan

xyz axis light distribution ruler (accuracy level 0.1um)

3 sets

changchun

dimensions of cast iron workbench: 600 in x direction, 500 in y direction, thickness 50 (with t-groove)

1 set

self-control

marble body, marble crossbeam

1 set

shandong province

cast iron mechanical accessories

full set

self-control. m

double row straight row tool magazine

18 digits

knife changing method

automatic

spindle speed

36000rpm/min

clamping tool handle

hske32

knife alignment method

automatic

the countertop bears a load

300kg

rated voltage

380v/50hz

maximum power of the entire machine

10kw

overall weight

about 2500kg

4、 standard configuration and accessories for the host:

one

controller

eleven

1 mechanical, electrical, and operation manual

two

electric spindle hske32-100-36000

twelve

rigid tapping function

three

automatic lubrication system

thirteen

electrical box heat exchanger

four

adjustable foundation cushion block

fourteen

operation manual, program manual, and user manual

five

toolbox

fifteen

hsk-e32 tool holder 2 (wrench)

six

work lights

sixteen

1 hsk-e32 locking tool holder

seven

warning lights

seventeen

m10 ma tie 1 set

eight

spindle blowing device

eighteen

nine

transmission line

nineteen

lock nozzle (4-10) 1 set

ten

fully enclosed cover

twenty

shield

5、 machine environment and hardware facilities requirements:

number

environmental projects

project requirements standards

one

power requirements

ac380v (4p) 50-60hz, air switch 60a, power supply voltage fluctuation range 380v± within 10%

two

air compressor

using screw compressor, air storage tank, three-stage filtration,≥ 0.55mpa, flow rate